Train automation for large-scale change

Optimise your load-out process for improved capacity, profitability and safety.

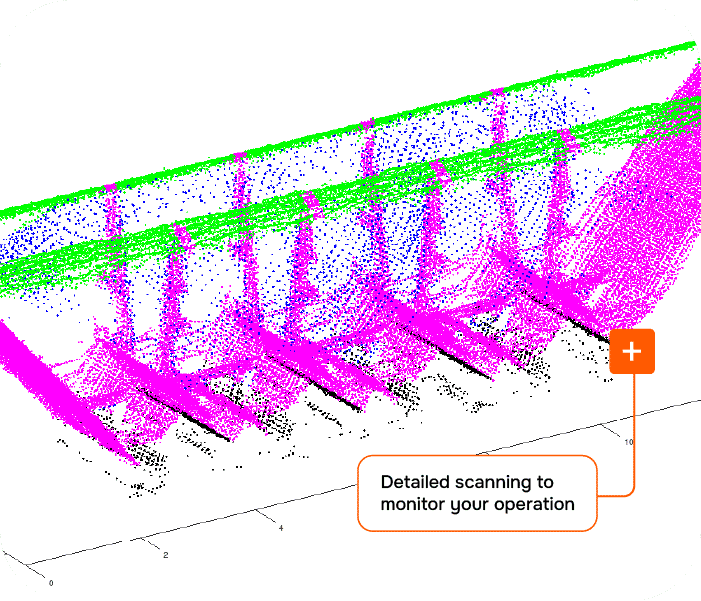

Axo33 TRAINS™ is an automated train load out and dump station monitoring system with real-time analysis, reporting and PLC interfacing. Experience pioneering technology in train automation.

Digital twin for train automation

De-man and de-risk your load out process

De-man and de-risk your train load out and unload processes with minimal hardware. Ensure accuracy and safety with powerful analysis that refines your volumetric model and saves money on hardware and heavier assets.

Experience train automation with uniform and symmetric profiles. Achieve optimised performance with accurate laser-based train speed and position monitoring. Increase throughput with real-time load profiling that ensures every wagon is loaded consistently and to maximum capacity.

Avoid fines for overloading and inefficiencies of underloading. Audit performance and operations for traceability and improvements with multiple train playback.

.webp?quality=low&width=700&height=600&name=digital-twin%20(1).webp)

Trace, audit and detect with confidence

Maintain control and reduce risk

See everything in one place for greater traceability and auditability of your train automation. Remove manual process and variable performance, eliminate wagon over or under loading and poor reliability. Detect potential derailments before they happen - as soon as a wheel leaves the rail.

Automate wagon door detection, preventing spill-out. Get multiple layers of data to calculate for adverse situations, offering accuracy and eliminating downtime.

Rapid integration with your own systems

Achieve enduring performance improvements

Finally - software that is specifically designed to integrate with your own systems quickly and easily. With Axo33 TRAINS™, maintain control over long-term support and maintenance by self-inspecting and maintaining your systems with ease.

Experience the freedom of less hardwards investment, and get more out of the assets you already have. Maximise uptime and lower your total cost of ownership. Achieve continuous improvement - on your own terms. Get high-value support when you need or want it through certified integrators.

FAQs

How does Axo33 TRAINS™ accurately monitor train speed?

Axo33's Speed Reader is a standalone monitoring and data logging solution that calculates highly accurate and reliable measures of speed continuously.

How do your train automation sensors adjust calculations for changing environmental conditions?

Vision-based systems alone are subject to accuracy issues due to changing environmental conditions. As laser and sensing technologies have advanced, they now provide a more reliable alternative that is not as vulnerable to weather and other harsh environmental influences. Laser scanners and RFID tag readers pass data to the PC-based server that filters and analyses data before communicating directly with your own PLC, for ultimate data processing and control.

How do we maintain more control over our own systems and reduce dependence on partners?

Axo33 is hardware-agnostic, which means you can purchase off-the-shelf spares or replacement hardware without being beholden to us. While we do have high-quality certified support partners (including ourselves), our aim is to provide solutions that are fit-for-purpose, modular and integrate with your own systems. If our systems go offline, they won’t bring yours down, and you should be able to inspect and maintain all software and systems yourself.

Can you demonstrate a track record of successful train automation projects?

MRA was involved in the very first automation of a train load out in Australia, using Axo33 Smart Automation Products. Since then, we’ve performed ongoing improvements and enhancements to our software.

Train Loading Automation for Anglo American

Anglo American is the world's third-largest exporter of metallurgical coal. The company uses the latest technology to run their operations in the best possible way and strive for continuous improvement at existing assets. They produce and export quality steelmaking coal, which is used in steel production for critical building and infrastructure around the world.

Coal is often transported from the mines to ports using hopper wagons on railway infrastructure. Railway infrastructure has many restrictions and requirements around loading weights, overloading, and inconsistent loading, issuing fines when restrictions are not allowed. These restrictions are in place because not following them increases the likelihood of damage to the railway, train derailments, and injury.